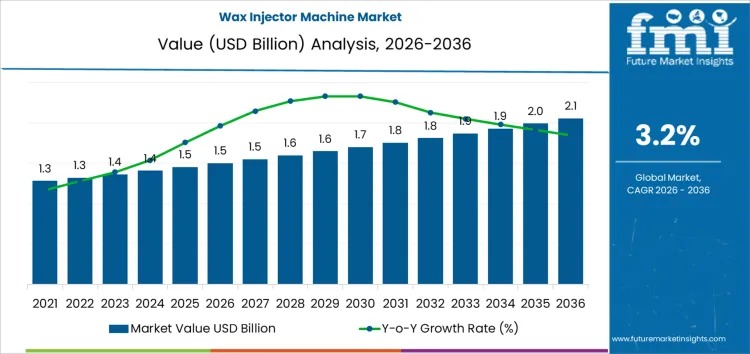

Precision casting demand drives Wax Injector Machine Market toward USD 2.1 Bn by 2036 at 3.2% CAGR.

NEWARK, DE, UNITED STATES, February 17, 2026 /EINPresswire.com/ — The global Wax Injector Machine Market is projected to expand from USD 1.5 billion in 2026 to USD 2.1 billion by 2036, reflecting a steady CAGR of 3.2%. Growth is closely tied to rising precision requirements in jewelry casting, dental prosthetics, aerospace components, and industrial investment casting, where wax pattern quality directly influences final metal integrity.

Unlike conventional machinery markets driven by volume expansion, this sector advances through quality optimization. Manufacturers are investing in temperature stability, injection repeatability, and automated controls to reduce downstream scrap and rework costs.

Request For Sample Report | Customize Report | Purchase Full Report –

https://www.futuremarketinsights.com/reports/sample/rep-gb-31298

Market Overview: Growth Anchored in Precision Manufacturing

Wax injector machines play a critical role in lost-wax casting workflows. Dimensional accuracy and surface finish are largely determined before metal pouring begins, making injection stability central to production economics.

Key Market Metrics

– Market Value (2026): USD 1.5 Billion

– Forecast Value (2036): USD 2.1 Billion

– CAGR (2026–2036): 3.2%

– Leading Product Type: Automatic wax injector machines

– Leading End-Use Industry: Jewelry casting

– Key Growth Regions: Asia Pacific, Europe, North America

Demand is primarily triggered by modernization of casting operations, tighter tolerance requirements, and yield stabilization initiatives rather than general equipment replacement cycles.

Product Type Insights: Automation Gains Market Share

Automatic wax injector machines account for approximately 44% of global demand. Their ability to maintain consistent injection pressure, thermal control, and cycle repeatability supports high-volume, precision-sensitive production environments.

Product Segmentation Highlights

– Automatic Machines: Dominant share due to process stability and defect reduction

– Semi-Automatic Machines: Balance between flexibility and control

– Manual Machines: Used in prototyping and small workshops

– High-Capacity Industrial Injectors: Deployed in multi-cavity foundry operations

As casting workflows become more synchronized, injection stability is increasingly viewed as a strategic investment rather than a support tool.

End-Use Analysis: Jewelry Casting Leads with 48% Share

Jewelry casting represents nearly 48% of total market demand. High production volumes combined with strict surface finish and dimensional requirements make injection consistency economically critical.

Major End-Use Segments

– Jewelry casting

– Dental prosthetics

– Foundry and industrial metal casting

– Model and pattern making

In jewelry production, even minor wax-stage defects can propagate through the casting cycle, leading to precious metal losses and increased labor costs. This economic sensitivity supports continued equipment upgrades.

Regional Growth Outlook

Growth trends vary by manufacturing maturity and modernization pace.

Country-Level CAGR (2026–2036)

– India: 3.8% – Driven by expanding jewelry and dental sectors

– China: 3.5% – Supported by large-scale casting clusters

– Brazil: 3.1% – Adoption in mid-sized workshops

– United States: 3.0% – Replacement demand and aerospace programs

– United Kingdom: 2.8% – Quality-driven upgrades

Asia Pacific remains the fastest-growing region, fueled by workshop formalization and automation adoption. Developed markets show stable replacement-driven growth linked to yield optimization.

Market Dynamics: Yield Stability Over Throughput

The Wax Injector Machine Market is increasingly shaped by yield stability rather than injection speed alone. In investment casting, pattern defects often remain undetected until later production stages, multiplying cost exposure.

Core Demand Drivers

– Rising complexity of aerospace and medical castings

– Greater automation in jewelry production

– Increased focus on scrap reduction

– Need for programmable pressure and temperature profiles

Foundries are prioritizing machines that deliver predictable behavior across extended production runs, reinforcing long-term equipment value.

Competitive Landscape

Competition centers on thermal regulation precision, programmable injection profiles, and service support. Established engineering firms such as Woodward Inc. and ABB Group operate alongside specialized manufacturers including Moldmaster (Wuhan Jingke), RDM Worldwide, Lindberg/MPH (Quintus Technologies), Mecosan SA, Shimpo Co., Ltd., Thorwesten GmbH, and HWM (Hot Wax Machines).

Differentiation Factors

– Temperature control stability

– Shot repeatability

– Mold adaptability

– Energy-efficient heating systems

– After-sales technical support

Suppliers that integrate performance documentation with strong service networks maintain competitive advantage in precision-sensitive casting programs.

Long-Term Outlook

Between 2026 and 2036, the Wax Injector Machine Market will advance steadily as casting operations prioritize process control and repeatable output. Growth will stem from modernization projects, precision upgrades, and yield-focused capital investments rather than rapid capacity expansion.

As casting tolerances tighten globally, wax injection stability is becoming central to profitability across jewelry, aerospace, and industrial manufacturing environments.

Get data that aligns with your strategic priorities — ask for report customization today:

https://www.futuremarketinsights.com/customization-available/rep-gb-31298

Related Reports:

Japan Compact Construction Equipment Market- https://www.futuremarketinsights.com/reports/japan-compact-construction-equipment-market

United Kingdom Compact Construction Equipment Market- https://www.futuremarketinsights.com/reports/united-kingdom-compact-construction-equipment-market

Gulf Countries Compact Construction Equipment Market- https://www.futuremarketinsights.com/reports/gulf-countries-compact-construction-equipment-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us – sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware – 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content “as is” without warranty of any kind. We do not accept any responsibility or liability

for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this

article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

![]()